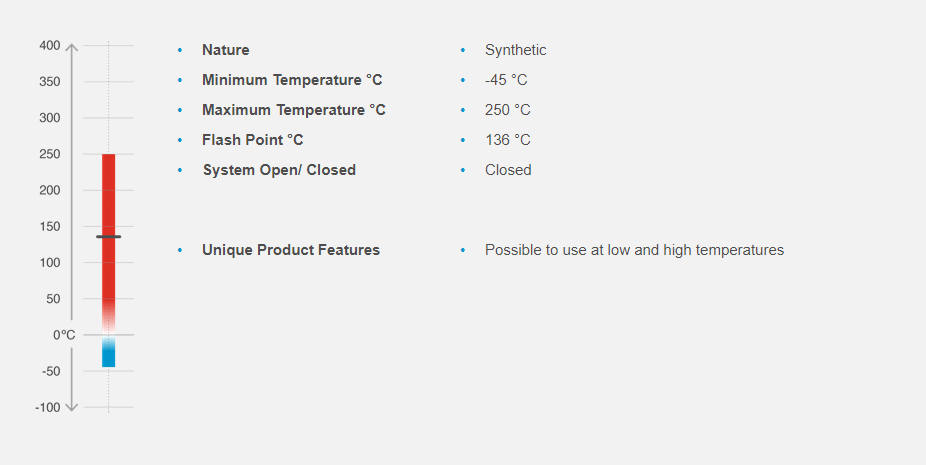

Caltherm CADX10 is a synthetic, low-viscosity heat transfer fluid designed for both heating and cooling applications. Its formulation allows for efficient system operation in low-pressure environments and is suitable for a broad temperature range from -45°C to 250°C. The fluid’s low viscosity makes it an ideal solution for systems that require easy start-up and efficient operation at lower temperatures.

Applications

• Suitable for temperature regulation in storage tanks requiring consistent thermal control.

• Utilized as a heat exchanger for both hot and cold loops across various industrial settings.

Advantages

• Provides efficient thermal transfer for reliable heating and cooling.

• Maintains excellent thermal stability during operation.

• Features very low viscosity, facilitating easy start-up even at low temperatures.

• Delivers excellent pumpability, ensuring smooth fluid movement within systems.

Caltherm CADX10: Expanded Applications

-

Chemical Processing

Caltherm’s high-tech thermal fluids ensure precise temperature control during synthesis reactions that generate exothermic or endothermic phenomena.

-

Industry Laundry

In the industrial laundry sector, Caltherm fluids offer long-lasting, even heating for laundry with quick start-up and non-toxic peace of mind.

-

Oil and Gas

Caltherm's synthetic thermal fluids excel in oil and gas production, ensuring peak efficiency from -50°C to 400°C, meeting crucial viscosity and flashpoint standards for optimal water removal.

-

Pharmaceutical Processing

Caltherm's thermal fluids cater to pharmaceutical needs with options for extreme temperatures, versatile ranges from -50 °C to 300 °C, and specialized fluids for open circuits up to 195°C, all featuring superior oxidation resistance and low toxicity.

-

Plastic and Rubber

Caltherm thermal fluids enhance mold thermal regulation in plastic/rubber industries, ensuring quality, efficiency, and material savings, with advanced compounds for safety and optimal circulation in various mold designs.