Achieving the perfect confectionery product involves meticulous attention to detail at every step of the manufacturing process. From balancing the essential ingredients to applying finishing touches, each phase contributes significantly to the quality of the final product. This guide outlines a step-by-step approach to perfecting your confectionery items, ensuring they meet the highest standards of quality and consumer satisfaction. Read on to discover how to optimize each stage to create superior confectionery products.

Step 1: Recipe Balance

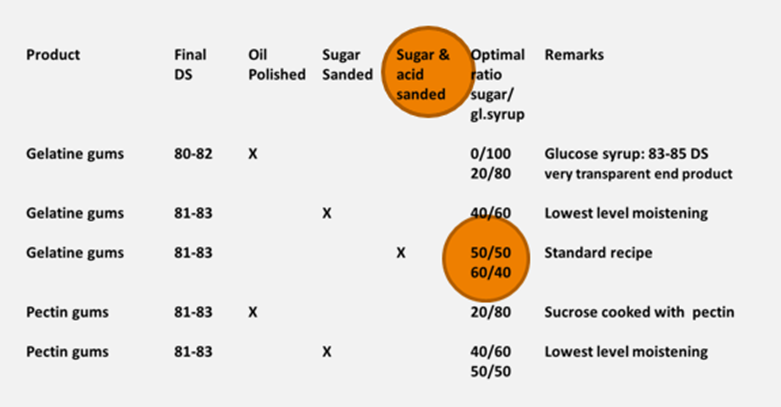

Sugar and Glucose Ratio: The foundation of a superior confectionery product lies in the correct balance between sugar and glucose within the confectionery mass itself. Sugar sanding with only sugar vs sugar sanding with sugar/acid/salt makes a difference with regard to the sugar/glucose ratio.

Step 2: Sanding

Use of Low-Pressure Dry Steam: Apply low-pressure dry steam (condensed) sparingly to the sweets. The goal is to moisten the sweets just enough to allow the sugar blend to adhere to their surface without dissolving or damaging the product. Keep the sanded gums max 2-3 min in the blender. Once this is done, products can leave the blender.

Step 3: Drying post-sanding

The products should be transferred to open trays for drying. Avoid overfilling the trays (so no thick layer) to give the products the possibility to become dry. Min. 24 hours.

Special consideration

For very sensitive product, we can add 3 % maize starch in the mix. This addition helps fill any surface holes and absorbs excess moisture.